Operational readiness is the most fundamental prerequisite for any protective effort and has consequences for practically everything we do as an executive protection company.

In this blog, we will be discussing how our understanding of this all-important concept is evolving – and encourage everyone in the executive protection industry – colleagues, competitors, and customers – to join us in this continuing discussion.

Just what is operational readiness? And how does it compare to operational optimization?

“Operational readiness” is a concept with military roots. The Department of Defense’s Dictionary of Military and Associated Terms defines it thus:

“The capability of a unit/formation, ship, weapon system, or equipment to perform the missions or functions for which it is organized or designed. Also called OR.”

The way the term is often used, both in the military and elsewhere, refers to a state: either you’re in a state of operational readiness, or you’re not – or you’re somewhere in between. In this sense, people talk about operational readiness rates, the degree to which people or systems are capable of doing what they’re supposed to do.

This is all good, and EP teams can also be assessed according to their readiness on a percentage scale. We do this with things like physical fitness tests and certifications, as well as other qualification standards. But this way of thinking can lead to a static, check-the-box-and-move-on mentality. When it comes to executive protection, we believe it’s even more helpful to understand operational readiness in terms of a process, not a state.

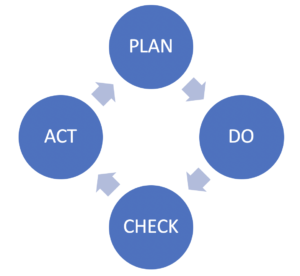

The state of operational readiness is a more like a goal towards which we must continually strive, something which we always work for through a process we prefer to call operational optimization. Operational optimization is more related to what quality experts call the “continuous improvement cycle”, the “Deming Cycle”, or the “PDCA Cycle”, for Plan, Do, Check, Check, and Act. In business process and quality management circles, these all refer to something similar: the organization’s ongoing march to improve quality, products, processes or services. This can happen incrementally, or all at once.

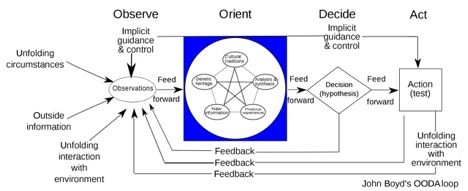

Another term that originates in the military, but also applies in many other contexts, is the OODA Loop. This is another take on the process of continual improvement, but one with a twist. The U.S. Air Force developed it to help fighter pilots understand how to come out on top of a confrontation, even if they were the underdog in terms of power, by reacting more quickly – and more skillfully – than their opponents in dynamic combat situations. In addition to its original military applications, the OODA loop is now commonly associated with agility – whether regarding agile project management or agile business management. Staying informed of the context, moving fast and adeptly, testing hypotheses – and repeating the whole process as needed – has won a big following in many industries.

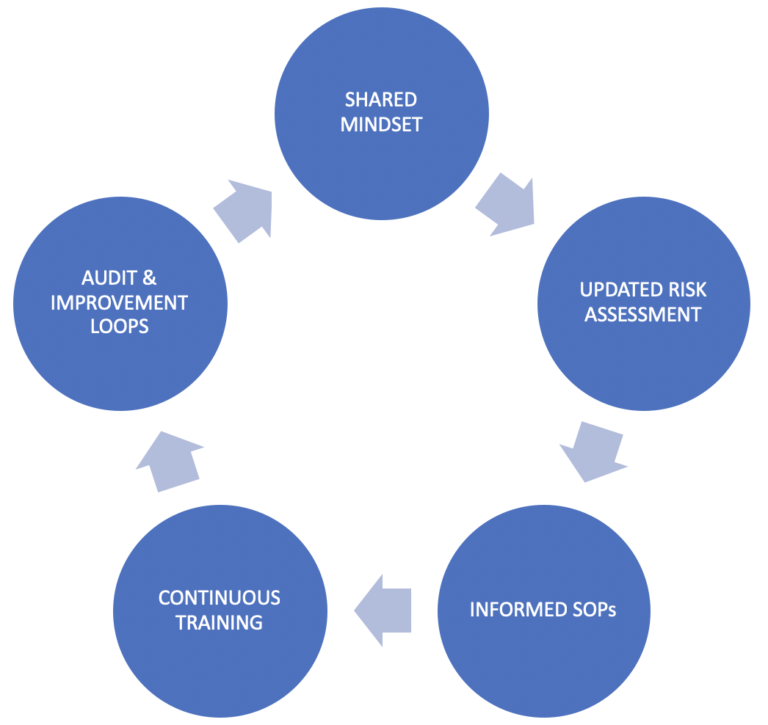

Below, we make a first attempt to how we believe operational optimization can be approached in the business of executive protection. Consider this combination of ideas, too, as a process – not a fire-and-forget proposition. Let’s now take a closer look what we call the five guiding principles of operational optimization in executive protection.

Principle 1: Establish a shared mindset of continual operational optimization

It all starts with intent and a shared sense of purpose. Unless everyone involved in trying to optimize the effectiveness, efficiency, and flexibility of an executive protection project the desired results are not likely to occur. And who is “everyone”? Well, that would include a wide variety of stakeholders on both the provider and client sides of the equation.

Within the EP team or the EP service provider company, this obviously includes agents and team leaders. If these frontline team members are not living and breathing for continual operational improvement, it’s not going to happen.

But operational optimization also starts at the top and must permeate all levels of the service provider organization. Senior leaders must realize that operational optimization efforts are about winning hearts and minds as much as following up on KPIs and performing audits. And they must act accordingly in how they manage and make related decisions.

Those assigned with quality assurance responsibilities must move beyond the commonly perceived role of “quality cops” looking for faults, and, rather, adopt an approach that centers on making all of us better at what we do. They will need all of their coaching and influencer skills to pull this off. They should not only be interested in finding quality gaps and fixing them; they must also seek to discover best operational practices then share and evangelize these relentlessly throughout the organization. Sharing such best practice is more likely to result in success for service provider companies that have a certain scale than they are in a siloed or smaller organization.

Executive protection clients – including the protected – must also share in the mindset of continual operational optimization. As we will see below, this mindset has consequences for everything from shift scheduling to training expenses and overall program quality standards and budgets. We in the industry need to get better at setting and managing expectations that promote operational optimization – in everything from RFPs to SOWs and contract negotiations – and partner with all relevant stakeholders our client’s organizations to ensure that these are understood.

Principle 2: Base continual operational optimization processes on valid risk assessments

Corporate executive protection is all about mitigating perceived risks as effectively as possible with available resources. While clients and providers can’t always agree on all the resources necessary to do this, we must all at least commit to perceiving these risks as clearly as we can.

Whether we conduct full-blown RTVAs or quick and dirty risk assessments, it’s important that these risk assessments occur on an ongoing basis. Everything changes – including the threats and vulnerabilities we must mitigate. Businesses expand into new markets with new conditions. Geopolitical realities shift. A principal’s prominence may wax or wane, and a corporation and its leaders might be subject to more or less scrutiny – not all of it positive – as news cycles roll on in search of the next headline.

The organization’s culture and the personal preferences of the principal must also be considered in what these dynamically changing risk assessments mean for mitigation. Ideally, risk scenarios should be addressed in a shared forum between service providers and clients on a quarterly basis.

Principle 3: Continuously optimize informed standard operating procedures

Standard operating procedures are the critical building blocks of any executive protection program.

To be an effective part of ongoing operational optimization, it is vital that these SOPs are informed by a number of considerations. Covering everything from processes to people and tools, they must:

- Build on industry best practices

- Be based on the dynamically updated risk assessments we mentioned above

- Be so actionable that they enable agents and managers to know what to do when in both routine and emergency situations

- Be amenable to ongoing, agile improvement through their transparency and communicability

Principle 4: Establish and implement ongoing training that supports program goals

When we are sure that our SOPs are properly informed, it is time to turn our attention to training, perhaps the most overseen link on the continual improvement chain. In terms of continual operational optimization, we draw attention to three factors that underscore the importance of ongoing training.

1. Executive protection skills are multi-dimensional, and so must be the training methodologies

The skills necessary to sustain effective executive protection programs include both what we often refer to as “hard”, (e.g. protective procedures, first aid, driving, and martial arts) and “soft” (things like interpersonal skills, knowing how to operate a business within a business, communication, etc.). All must be addressed as training addresses gaps in readiness on individual and team level, and as situations change.

The training methodologies suitable to build relevant skills are similarly varied. In some cases, completing an online course will be sufficient. Tabletop training during shifts will do fine for other needs. In some cases, offsite courses with theoretical and practical components are called for. Finally, let’s not forget the importance of on-the-job training. This is where employees acquire and hone skills in the real-life contexts of everyday operations – and a critical part of leadership development and career progression.

2. Executive protection skills are perishable, and training must serve to continually refresh them.

It is important to understand training as an ongoing process that is key to the protective endeavor, not a box to be ticked off and forgotten about. In one way or another, almost all the skills necessary for performing best-in-class executive protection are perishable.

Some of the skills necessary to perform executive protection are, fortunately, rarely needed. We must master them anyway. If circumstances call for CPR or evasive driving, for example, we must be able to demonstrate these skills even though they occur in outlier situations. It is not good enough if an agent has relevant courses on his or her CV: the principal must be assured that the skills are up to date and ready to be deployed – now.

3. Executive protection training requires resources to complete, and this must be transparent to both providers and clients.

It might seem obvious, but training doesn’t occur spontaneously on its own. It has to be prioritized, planned – and paid for. All too often in contract negotiations, responsibility for covering training costs is either not considered or tactically avoided.

No client wants second-best executive protection for their principal. We in the industry need to get much better at making the necessity, benefits, and costs of training in RFPs and SOWs. And we need to address these issues in a transparent way in every step of the client-provider relationship.

Principle 5: On-going audit and improvement loops must be an integral part of the protective program.

Finally, let’s turn to a cornerstone of all quality improvement programs: the audit. This is where we assess how we comply with agreed quality criteria regarding processes, people and tools. This is where we discover and analyze gaps – in order to then fix them.

As we develop our own system of quality audits, some things have become clear. For one, as mentioned above, a shared mindset is critical. Ours is a profession that employs a lot of alpha dogs. If audits turn into turf battles between all these hounds, with one doing most of the sniffing, audits won’t produce the desired results. It is far better to understand audits as opportunities to improve our services – and the entire organization – for the benefit of all.

Another thing we have learned is that audits cannot stand by themselves. They form part of the “checks” in the iterative “plan, do, check, act” cycle described above. They are one part of a loop – not an end-station. Once we discover quality gaps, we need to activate all of the other guiding principles – adjusting SOPs and training, updating our risk assessments, and ensuring a shared mindset – in order to fix the gap. The process is never-ending.

Audits of executive protection programs are still relatively rare. However, as the industry continues to professionalize, we believe we will be seeing much more of them in the coming years. We expect that just like many other industries, ours will increasingly adapt ISO 9000’s principles of quality management as audits are prepared and implemented.

Although we have made a lot of progress towards operational optimization, both as a company and an industry, we have a long way to go before we get to the level of other industries. We look forward to your feedback and ideas on how we can improve this process and speed it up.